Our Product

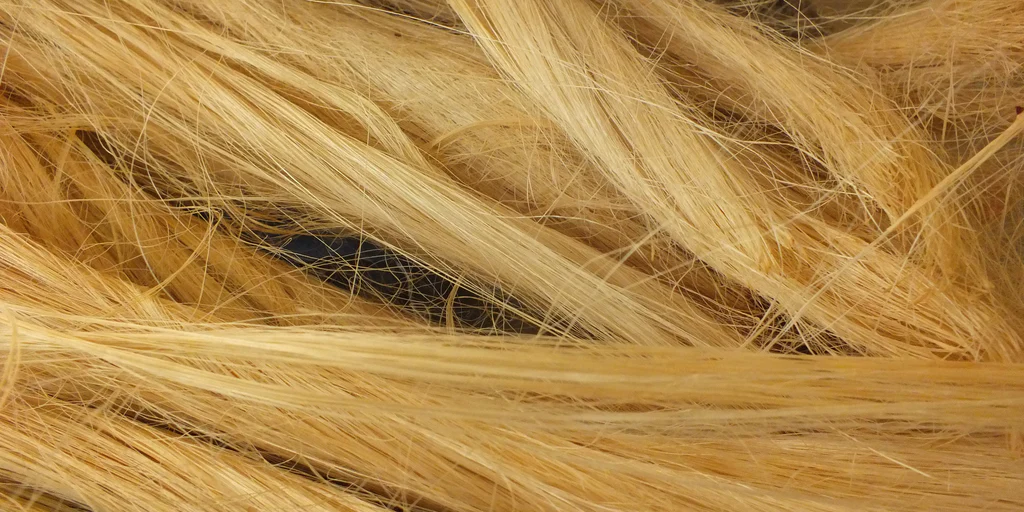

Cottonized Banana fiber

Banana fiber is a renewable resource derived from the pseudostems of banana plants by using mechanical process. It involves utilizing agricultural waste, which would otherwise be discarded and does not require harmful chemicals. Hence, the banana fiber production process is eco-friendly and sustainable. And as a result, this innovative material has gained recognition as a biodegradable fiber, making it a suitable choice for industries looking to reduce their carbon footprint. Notably, banana fiber is strong and durable, allowing it to compete with synthetic fibers on a performance level. Additionally, garments made from banana fiber are known to be soft and lightweight, providing a comfortable option for sustainable fashion enthusiasts.

Extraction process

Harvesting: Mature banana plants are carefully selected and harvested. The outer layers of the plant are removed, and the usable inner fibers are extracted.

Extraction: The extracted fibers undergo a process called decortication, where they are separated from the plant's stem. This can be done manually or by using mechanical decorticators.

Fiber Treatment: The extracted fibers are then washed thoroughly to remove impurities and dried to achieve the desired moisture content. This ensures the fibers are clean and ready for further processing.

Fiber Spinning: The dried banana fibers are spun into yarn using traditional or modern spinning techniques, depending on the desired end product. The yarn can be blended with other fibers to enhance its properties or used in its pure form.

Weaving/Knitting: The banana fiber yarn is woven or knitted into fabrics using traditional or advanced weaving/knitting machines.

Finishing: After weaving or knitting, the banana fabric undergoes finishing processes such as dyeing and printing, depending on the desired functional properties of the end product.

Attributes

Strength and Durability: Banana fiber possesses remarkable tensile strength, surpassing that of other natural fibers such as cotton or jute. This attribute ensures that banana fiber products are long-lasting and resistant to wear and tear.

Lightweight: Despite its strength, banana fiber is relatively lightweight, making it suitable for a wide range of applications. This characteristic adds comfort and ease of use to the end products.

Softness: Banana fiber features a soft and smooth texture, providing a pleasant sensory experience when used in textiles. It offers a luxurious feel against the skin, making it a preferred choice for clothing and other personal accessories.

Moisture Absorption: With excellent moisture absorption properties, banana fiber can effectively wick away perspiration and maintain a dry and comfortable environment. This quality is particularly advantageous for sportswear and outdoor apparel.

Thermal Regulation: Banana fiber exhibits natural thermal regulation, allowing it to adapt to changing temperatures. It provides insulation during colder seasons and ensures breathability in warmer climates.